Products

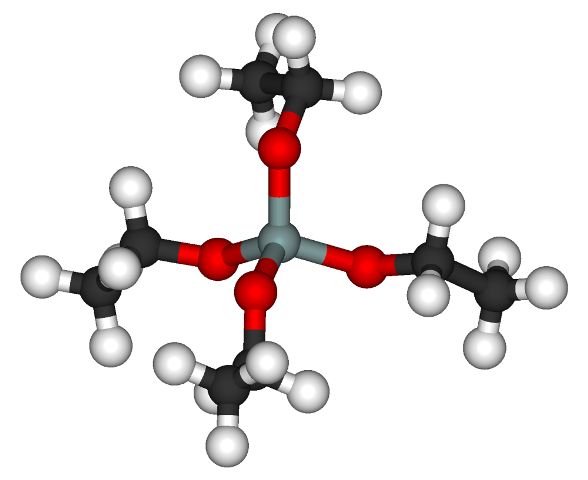

- CHEMICALS & RESINS

- GLUES & ADHESIVES

- VARNISHES & WAXES

- CLEANING AGENTS

- LABORATORY WARE

-

LABORATORY EQUIPMENT

- POWER TOOLS & AIR TOOLS

-

HAND TOOLS

- MAGNIFICATION & LIGHTING

- LABORATORY INSTRUMENTS

- ENVIRONMENTAL MONITORS & DATALOGGERS

- BOOK & PAPER CONSERVATION

-

BUILDINGS WALLPAINTINGS AND MOSAICS CONSERVATION

- STORAGE - DISPLAY - PACKAGING - TRANSPORTATION

- PERSONAL PROTECTION

- MISCELLANEOUS SUPPLIES FOR LAB & EXCAVATION

- BRUSHES & RESTORATION COLOURS

- FABRICS & TEXTILES